If you want to find a way to keep track of your company’s inventory and ensure that you don’t run out of products, then a barcode system is the way to go. Barcode inventory systems are a great way to track your products and identify the status of items, but implementing them can be challenging.

The following blog post will guide you through all the steps to get started with this process. You will learn what barcodes are and how they work, and other information such as benefits and drawbacks. We also discuss some considerations when choosing a software provider for your business.

What is a Barcode System?

A barcode system is a way to keep track of your inventory by assigning each item an individual number, which you can then scan and identify when necessary. A barcode helps you know the exact location of products at all times to avoid any errors or accidents that may result from running out of items on hand.

You will also never lose track of stock-outs since you’ll always know how many units are available for purchase.

What Are the Different Types of Barcodes?

There are several different types of barcodes that you can use for your inventory system. You should choose the one that best fits your company’s workflow and is compatible with the available technology to avoid any delays in the process. The following list details each type:

Linear Barcode

These codes consist of lines arranged in specific patterns, which laser scanners or similar devices can read. A linear barcode makes it ideal if you want a code that includes alphanumeric characters while providing maximum flexibility for data input.

Two-Dimensional Barcode

Two-dimensional barcodes are consist of multiple lines arranged in a specific configuration. It can include more data than its linear counterpart and is ideal for product identification since it contains numbers and letters.

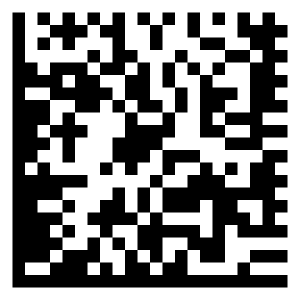

QR Codes

A QR (Quick Response) Code is a two-dimensional barcode that allows you to store long alphanumeric strings within the black squares found on most smartphone screens.

The advantage of using this system is that users don’t need any additional hardware or software to read them, making sharing information with customers easier.

Data Matrix

The last two-dimensional barcode is the Data Matrix code, consisting of squares arranged in a specific pattern. It can include product codes and serial numbers for products that require absolute precision when tracking information about them.

How To Implement A Barcode System For inventory?

Since barcodes are used to track inventory, placing them on each item you’re using for your business to make the system work is no longer necessary. However, this is easier said than done. It can take some time depending on how many products your company manufactures or purchases every month.

The following steps will guide you through the process of implementing a barcode system:

Determine Which Items To Label With Barcodes

You should begin by identifying which items are necessary for running your business. You may want to start with all high-value items first since these offer better returns when resold if lost. Then go down to the end of the list so there won’t be any surprises later about what needs labeling immediately.

Prepare Your Inventory For Barcodes

This step involves either finding a way to affix the barcode labels directly onto your products or using stickers that can attach them for you. You should also take this opportunity to remove any unnecessary packaging to not interfere with how scanning later on.

Ensure items are clean before applying their respective labels to scan correctly without needing additional cleaning afterward.

Identify The Type Of Barcode To Use

Identifying the different types of barcodes and what works best for your business is essential. It will determine which type you should use for your inventory system and how many codes each item can store.

Once you decide on this, identify the best location to place it for accurate scanning.’

Prepare And Apply The Barcode Labels

If you’re using pre-made barcodes, all that’s left to do is follow the instructions provided with them to apply these to your products.

If not, create a unique code. You can do it by using either numbers or letters. It depends on what kind of data needs tracking alongside any other relevant information related to its application, such as product name or serial number if needed. Then find a location to attach them for them to be scanned when necessary.

How eSwap Makes Inventory Management Easy

eSwap provides numerous features that help make inventory management an easy process. It can include:

One-screen for all inventory

They have created an easy design wherein all inventory is displayed on one screen, making it easier to manage. This allows users to view all stocks for each item, easy per channel filtering, and many more.

Multi-variant products inventory management

Their management software allows users to control product variant stock completely and create purchase orders to get new supplies. The system also has information regarding the different dimensions for making correct shipping estimations.

Archive for your inventory

A separate archive to help inventory management for seasonal products much more manageable is available. The archive includes details about prices, inventory, images, and many more. You also have the option to un-archive the products when you need them.

The Bottom Line

With the right barcode system in place, you can quickly and easily identify which products require attention or need replacing entirely. Having the correct barcode will also save your business time and money while increasing its overall efficiency.

Implementing a successful barcode inventory system is essential if you’re looking to stay competitive with other companies that already have one put into place. In addition, it allows businesses of all sizes to follow strict guidelines regarding their product’s whereabouts. They can do it without needing additional employees dedicated solely towards this purpose.