Warehouse kitting involves gathering multiple SKUs (Stock Keeping Unit) and combining them in a package to create a new SKU. Order fulfilment via preassembling them into individual items in the form of ready-to-ship kits instead of picking and packing those individual items as orders are called kits.

What is Kitting in Warehouse?

Warehouse kitting as a method offers a high rate of savings in fulfilment costs. Kits include separate but related products grouped, packaged, and provided together as one unit or an entity.

Order fulfilment might be stressful and complicated for retailers and merchants, especially during the holiday season periods. Warehouse kitting could be the best answer to handle that problem. It helps the retailers and online business owners save time and money and optimize their inventory management.

After the order fulfilment for an individual product, a particular item gets a unique identifying code in the warehouse management system. After the order is placed a staff member calls back an item before updating inventory and order fulfilment. This process is repetitive for each ordered product as each individual product owes a unique SKU as all the items are picked, packed and shipped separately.

In the case of kitting, you bundle the products most of the times ordered together to create a single unit in your inventory. This system is a process that assumes an easy and quick item location as a bundle and shipping it off right away.

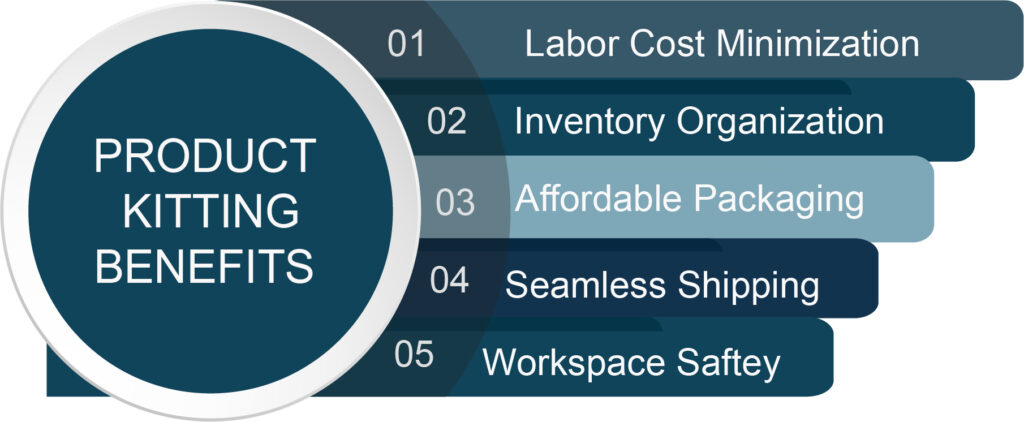

Warehouse Kitting: The Benefits

Warehouse kitting offers ultimate benefits for retailers and the companies striving to have a better inventory management system.

Here are the main advantages of warehouse product kitting.

Inventory Organization

The invaluable part of the warehouse kitting system is providing an overall organized and streamlined inventory management system. Using the product kitting system assumes generating fewer SKUs, inevitably allowing you to manage and organize your inventory efficiently. The warehouse management system will enable you to optimize your warehouse space and opt for a better organization.

Warehouse Efficiency

Increased efficiency is the second invaluable benefit of warehouse product kitting. Warehouse kitting helps to save your time and decrease labour costs. Kitting helps to perform your tasks with higher efficiency with fewer workspaces, ultimately lowering the labour costs and saving money & resources.

Labor Cost Minimization

Having reasonable control over your warehouse will help you to decrease labour costs. There will be demanded fewer workforces to manage your tasks, thus saving time and resources. Reduced labour costs are a huge asset for your company due to your business’s warehouse kitting system establishment.

Fast and Seamless Shipping

The establishment of warehouse kitting system apart from saving your time and resources supports having a quick and straightforward shipping process.

Human errors occurrences decrease due to the warehouse kitting and fulfilment services. The companies choose to print shipping labels in advance and label individual items at the time of shipping, offering considerable time, money and resources savings.

To save more time, you can quickly ship off the preassembled kits, thus reducing the fulfilment errors.

Affordable & Efficient Packaging

Warehouse kitting assumes the companies to have an affordable and efficient packaging system for their inventories. Imagine having a chance to pack your products together in a custom-sized box instead of packing them separately. That’s another asset of warehouse management & organisation system which ultimately helps to cut your packaging costs considerably. Kitting in warehouse helps to reduce the parcels’ space and weight and support spending less time and materials on packaging thus making it more affordable and efficient.

Warehouse Space Optimization with Product Kitting

Product kitting helps the companies to free up more space in the warehouses. Product full kitting is a big time-saver for companies. Product kitting and bundling similar items together helps optimize and reduce your warehouse space, allowing you to operate in smaller and more optimized warehouse space, saving your time and money.

Workspace Saftey

Every retailer once a lifetime experiences cases of inventory shrinkage as a safety issue. The investment of smart warehouse management improves workplace safety due to the reduced time and distance between the workers who assemble the orders and play an essential role in the order processing. An organized warehouse helps the retailers to improve workplace safety meaning to have a safer, more comfortable workplace and less time spent on labours due to the automated kitting.

Optimized warehouse management leverages as an efficient sales strategy for retailers. It provides a simple and effective order fulfilment strategy saving your business time and money without any mentions of having smooth and optimized shipping for your inventory.

Warehouse Management with eSwap

eSwap allows you to have organized inventory management due to the software features like multi-channel listing, inventory and order management, and shipping and warehouse management, creating and managing multiple FBA warehouses, getting a real-time inventory location reports, combining multiple sales channels of your inventory in one warehouse. Due to the location-based warehouse management feature, you are reducing your manual operations for inventory, getting bulk import orders from different platforms, controlling out-of-stock or low-stock information and your return management issues.