Running a business is all about optimization. Especially when we speak about the retail business, we mean lifetime inventory optimization. Low-stocking, overstocking, understocking…Surely you will say retailers should stock inventory according to demand. But I believe these situations are the most happening problems in a retail business. And every businessman should be ready to face them at the same time keeping your customers satisfied and happy. So, it’s just time to speak about how to calculate safety stock.

What is the safety stock?

Let’s just analyze the word itself. Safety stock…The term refers to an emergency stock for surviving any unexpected circumstances like breakdowns of machinery, unexpected weather conditions, or simply delayed stock deliveries. Consequently, this term is too essential for sellers to overcome supply chain challenges.

How to calculate safety stock?

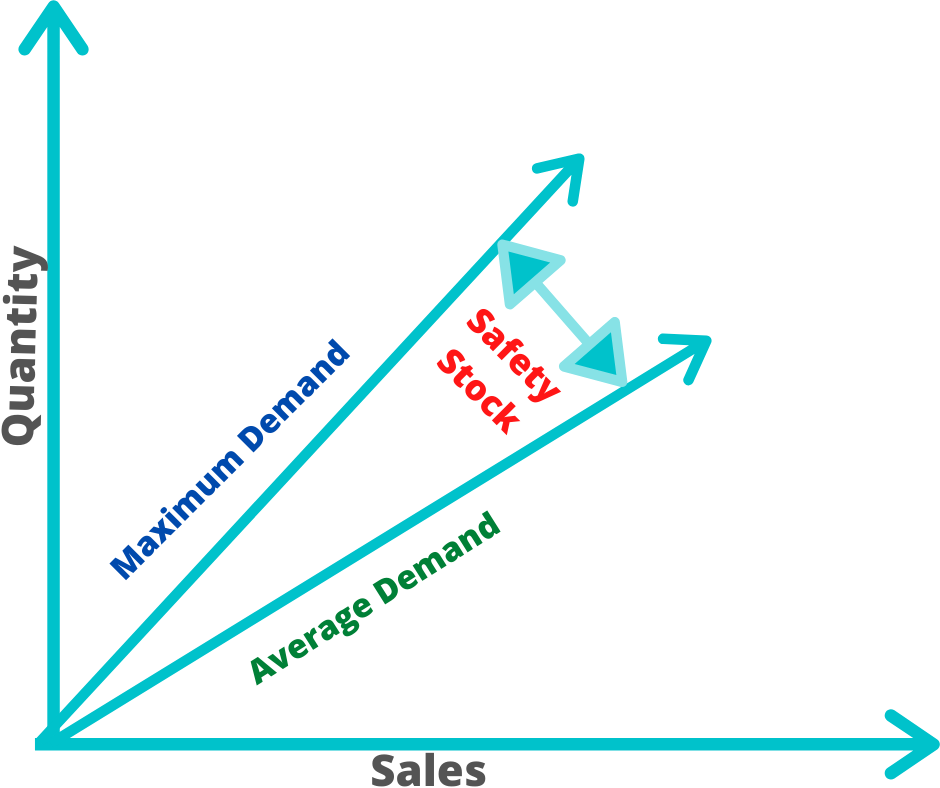

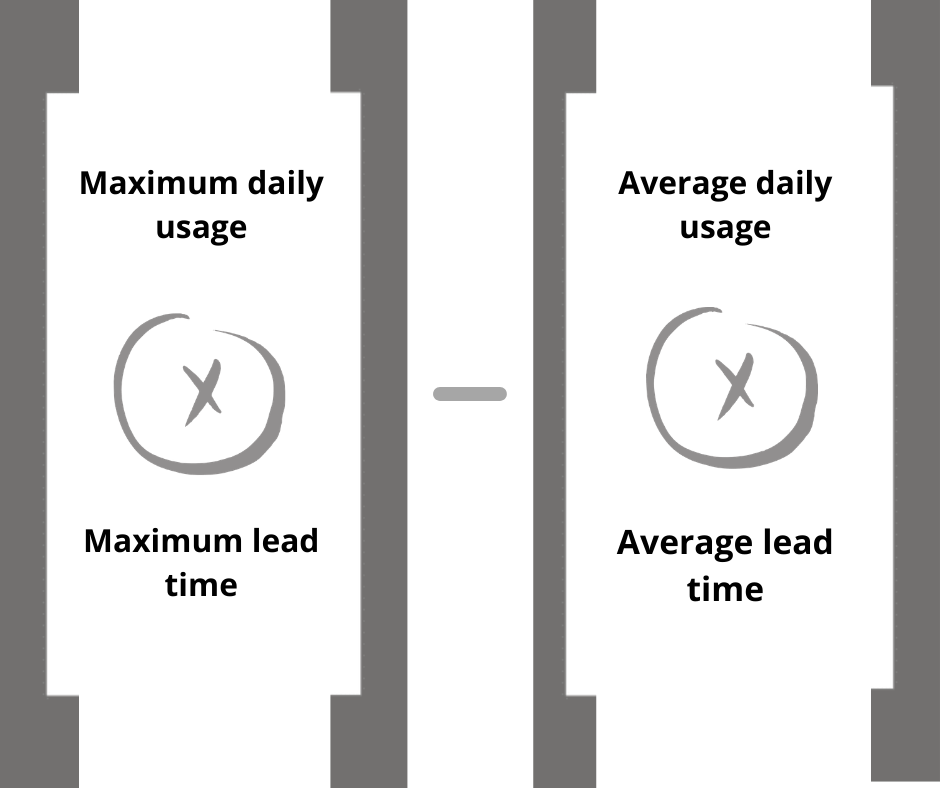

Safety stock is the volume of inventory between the maximum and average demands. For safety stock calculation the following general formula is used:

- Multiply, first of all, maximum daily usage by maximum lead time in days.

- Multiply average daily usage by average lead time in days.

- Calculate the difference between these two values

Other solutions on “How to calculate safety stock”

- Fixed safety stock

- Time-based calculation

- Heizer Render formula

- Greasley’s method

In stock management, there is another term to take into consideration: EOQ. EOQ refers to Economic Order Quantity. It’s a method of stock level calculation based on inventory holding costs and the demand. The accurate calculation will show the necessary amount of inventory to have on hand.

When is safety stock important?

- Price fluctuations of raw materials

- Failed or delayed deliveries

- High demand

Price fluctuations of raw materials

Sometimes markets can surprise retailers with price fluctuations caused by new competitors, suddenly increased demand, new terms in government policies.

What to do when the prices of the raw materials unprecedentedly rise?

Surely, if you have emergency stock for such cases it will be great. This will help you avoid buying high-priced stock. You may not even imagine how much you will win in this situation.

Failed or delayed deliveries

Retailers will confirm that there are situations where to get your product is impossible. The supplier fails to make delivery on time because of several acceptable or sometimes even not acceptable reasons. No matter if it is because of unpredictable weather, natural disasters, manufacturing failures, or financial problems, the fact is you stay without a product on hand. Again in such cases having a safety stock on hand seems to be the guarantee for saving your business.

High demand

Any retailer always faces interruptions in the supply chain because of eventually changing the demand for a certain product. This is also known as demand shock. Demand shock is an increased or decreased demand for products or services. Generally, sellers are fond of increased demand, but they even have no idea how it can become the end of their business. Finding yourself in a low-stock situation is one of the common ways to lose the chance to beat your competitors and finally lose your customers. Again and again…thanks to safety stock for keeping us safe in such cases. Having enough stocks on-hand allows you to meet all the requirements of your customers and fill the demand of the market.

Let’s have a glance at several reasons causing unexpected high demand:

- Decreased price of the product

- High Demand for the product

- The future cost of the product is going to increase

Benefits of safety stock

- No risk of running out of stock

- Overcoming unexpected circumstances connected with demand.

- Flexibility to order more products in case of not accurate demand forecasting

- Successful sellers and happy customers

Accordingly, we can confirm that keeping safety stock is too vital for any company. It’s like a helping hand given to a man drawing in water. Therefore any businessman should calculate the ideal quantity of stocks and overcome any unexpected supply chain challenges. Notably, today it is not as hard a task as many years ago.

In this modern world of technologies, there are many automated systems for inventory and order management allowing retailers to always keep control of stock levels while at the same time having accurate accounting and reporting.