When it comes to UPC stock management and SKU tracking, many business owners can feel overwhelmed. It’s necessary to learn the basics to make informed decisions about what system is suitable for your company. This blog post will discuss the main differences between UPCs and SKUs. In addition to this, we will also cover one of the most frequently asked questions on the web: “How do UPCs help with inventory control while improving your stock management?”

SKU VS UPC

A UPC, or universal product code, is a 12-digit barcode meant to identify products globally. Retailers use UPCs to scan and track items in their stores, and manufacturers also use them to encode information about their products. For a UPC to be valid, it must be purchased and licensed through the GS1. The abbreviation stands for Global Standards One – an organization responsible for business communication standards worldwide.

The UPCs are often confused with SKUs (stock-keeping units). However, these two terms cannot be interchangeable. Items from a single category sold by various retailers can have the same UPC, while the SKU is unique to each company. As a rule, each digit of an SKU identifies a product’s specific features and determines the retailers. Consequently, another difference between SKU and UPC codes is that unlike UPCs, SKUs are free to create and use. These are product codes used internally by businesses to track their inventory flow. One of the advantages of such codes is that they are appropriate for both physical products and abstract services.

Why Are UPCs Beneficial?

Many retailers use their UPCs instead of investing in an SKU system. From this perspective, UPCs can also be beneficial in inventory control. Firstly, UPCs are tied to products, not locations, thus, making the stock movements tracking more convenient even for items shipped between warehouses or stores across cities and even different countries. This makes it easier to keep track of inventory levels, identify missing items, and prevent stockouts.

Secondly, UPCs improve the speeds of stock operations. As a result, the production efficiency rises to its maximum through the utilization of code scanners. Thus, applying UPCs in the inventory management processes eliminates the need for typing each product’s information manually.

How to Define a Barcode?

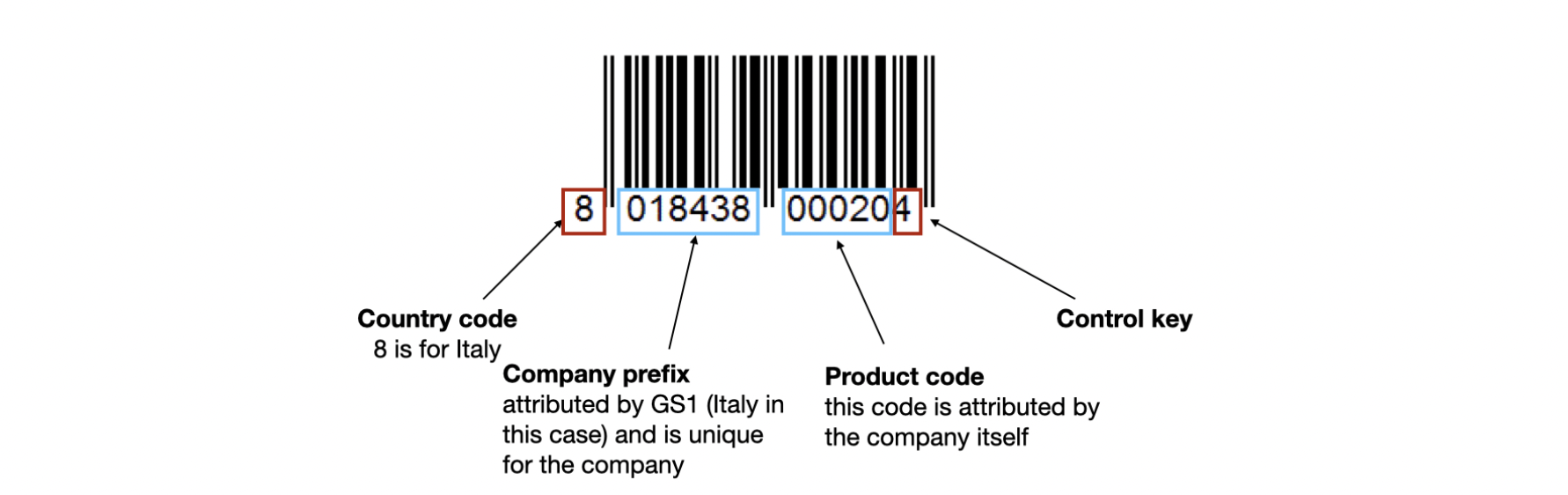

Image source: Nurideas

Barcodes are a machine-readable representation of data most commonly used to track inventory in stores. Barcodes can be either one-dimensional (linear) or two-dimensional (matrix). A 1D barcode is a black and white pattern that encodes information in variable-width lines and spaces. Such codes can also include numbers and sometimes letters. As a rule, a standard 1D barcode has a limited number of characters – 20 or 25. If the information to be encoded significantly exceeds the limitation, the barcode must be longer. In fact, UPCs are 1D linear barcodes read by scanners that convert the optical impulses into electrical signals decoded only by a computer.

2D barcodes are also known as QR codes. Such patterns are advantageous for they allow encrypting more than 2000 characters. In addition, it is possible to insert website addresses and even images into such barcodes for better results. Besides QR codes, 2D barcodes include PDF417 and Data Matrix.

The Composition of a Standard 1D Barcode

1D barcodes typically contain the following information:

- Country code

- Company prefix (unique for each one)

- Product code

- Control key

Implementing a UPC Tracking System

UPCs are an essential part of any stock management system. To use barcodes, you need a scanner and software that can generate and print barcodes.

There are two main UPC stock management systems types: handheld scanners and fixed readers. Handheld scanners are portable devices that employees can carry around and scan products stocked on shelves or pulled for customer orders. On the other hand, fixed readers are stationary devices usually installed near entrances or exits of the store. They are especially used to scan barcodes as products are brought in or taken out of the store.

Both handheld scanners and fixed readers have their advantages and disadvantages. For example, handheld scanners can be used to scan items that are not visible from the fixed reader’s vantage point. At the same time, they can also be more challenging to use in large stores. Fixed readers are less susceptible to interference from other scanning devices. However, they can be more expensive to install and maintain.

Many businesses wait until they are faced with an inventory crisis that costs them thousands of lost dollars. Developing an automated work environment is the choice of the most successful enterprises. When choosing a UPC stock management system, it is required to consider your store’s needs and the type of products you sell. There are many various options available. Nevertheless, integrating your barcode system with an inventory management system will be the wisest decision. Barcodes are a time-saving technology that significantly assists the employees in finding physical items in the warehouse within the shortest time. Implementing a UPC tracking system can help you control your inventory and ensure that your products are properly stocked. Thus, with the right system installed, you can streamline your operations and keep your business running smoothly.

Bottom Thoughts

In conclusion, UPCs are something to consider if you’re considering investing in a barcode inventory tracking system. In fact, entrepreneurs can develop more efficient and accurate production with a UPC stock management system.

UPC barcode tracking systems are a great way to manage your inventory and ensure accuracy in your product stock. UPCs offer global recognition, making it easy to track products no matter where they’re located. With this in mind, implementing a UPC tracking system can help you keep tabs on product levels, so you never run out of stock again.