Final products go through the long way of manufacturing. And the components having the leading part in this way are those that should be created or bought beforehand. The production process starts right when the manufacturer gets the raw materials. Therefore, the inventory in the process of becoming a finished product is the work in process inventory.

For example, an electronic teapot is a device that works when plugged into the electricity. But actually, it’s not the plastic that works, but small details inside the pot. And so that to calculate the final value of the pot, you also need to consider the raw materials, labour and production costs. This is how work in process inventory is essential. This article will tell you about work in process (WIP) inventory definition and how to calculate it. That’s the WIP formula.

Work In Process: Definition

The term work in process (WIP) inventory is widely spread and mainly used in the sphere of supply chain management. It relates to the overall costs of those goods that are non-finished yet or still in production. WIP inventory is a vital production step that is considered an asset on a company’s balance sheet. Sometimes it is considered to be even more important than the actual finished goods. Overseeing WIP is always a benefit for any business.

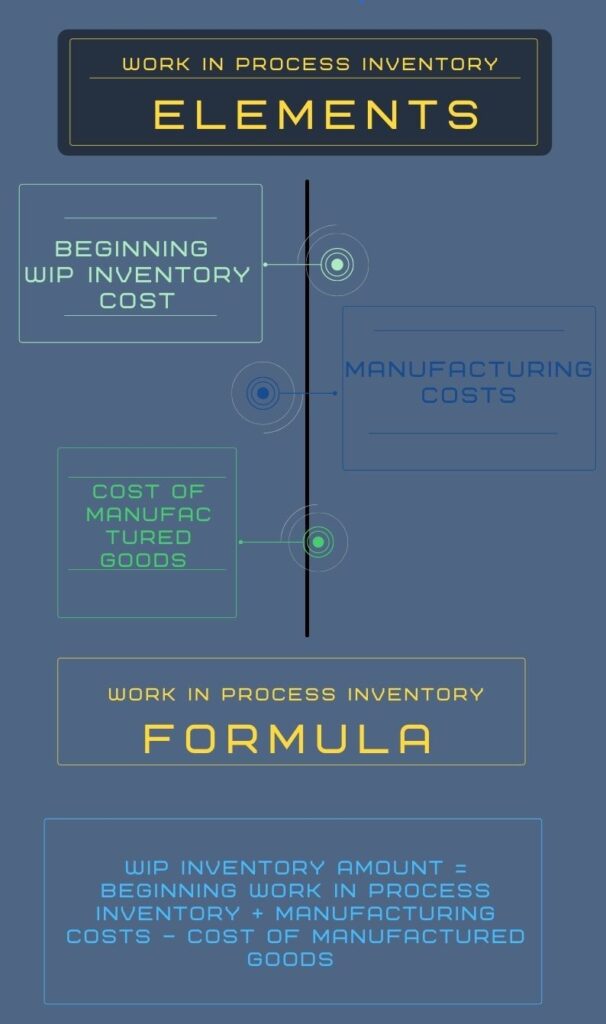

Elements of Work in Process Inventory

WIP inventory is a group of elements of finished goods. But it also has its components. So the cost of WIP inventory is complex as well. And it’s crucial to know its moving parts. Let’s specify them before finding out how to calculate work in process inventory value.

Beginning WIP Inventory Cost

This term refers to the past accounting period and shows the period’s asset section of the balance sheet. For beginning WIP Inventory Cost calculation, you need to define its contrary – the ending WIP inventory cost.

Manufacturing Costs

Manufacturing costs are simply all those costs that you can connect to the final good manufacturing process. It mainly is:

- Raw material cost,

- labour,

- overhead costs.

Suppose WIP inventory is higher while the production process, raw materials and labour costs will be high as well. This, in its turn, affects the overall costs of manufactured goods.

Manufacturing costs formula:

Manufacturing Costs = Raw Materials + Direct Labor Costs + Manufacturing Overhead

Cost of Manufactured Goods

This is a term showing overall costs needed for final product making. COGM is necessary for WIP inventory value calculation. For this, you need to sum total manufacturing costs to beginning WIP inventory. Then you take off the ending WIP inventory. Thus you will see your overall manufactured goods cost.

Manufactured goods cost formula:

COGM = Total Manufacturing Costs + Beginning WIP Inventory – Ending WIP Inventory

How to calculate the Work in Process Inventory?

When you know the main components of WIP and how to calculate them, you can now come to the point of thinking about the WIP formula. Any manufacturing company needs to know the correct amount of inventory. And it doesn’t matter whether it is in the form of raw materials or WIP inventory.

Note: Inventory management is interested in the aspect of these inventories as well. It helps to count and keep control of any type of inventory – including WIP. The precise number of stock will give an accurate idea of how much inventory to produce. It also will help to get based on the demand. From the financial point of view, wise business holders do this from the very beginning. It should be noted once more that this is one of the most crucial points in financial management.

Work in process inventory calculations should refer to the past quarter, month or year. The formula is as follows:

WIP Inventory amount = Beginning Work in Process Inventory + Manufacturing Costs – Cost of Manufactured Goods

Work in Process VS Work in Progress

It is important to bear in mind that work in process and work in progress are not the same as the majority can think. People sometimes use the 2 terms interchangeably, but they mean different things.

- Work in process is used to describes raw materials later turned into finished goods.

- Work in progress is a term mainly used in construction or other service-related businesses. It shows a particular project stage and its cost compared to the completing percentage.

WIP inventory is a point of supply chain management that will be helpful for its optimization and improvement. There is no successful online store that can go on and reach high results without inventory management. Those branches as warehousing, fulfilment, and others can be organized with the help of 3PL companies providing the best services and solutions. eSwap cooperates with leading companies like DHL, UPS, USPS, etc. With those integrations, we will help you run your business easier and more effectively. It will definitely make your customers happy.

Learn more about eSwap features, contact us, get pricings and enjoy the best experience with us.