If your business operates in retail or wholesale industries, one thing is sure: inventory is your primary asset, and you need a place to store it. It can be a type of distribution center or a warehouse. In both cases, warehouse management software (WMS) is integral to efficient operation.

When it comes to a warehouse, be it business-owned or third-party logistics, it will require purchasing or leasing land and facility, hiring employees, purchasing equipment, etc., to get it into an operational state. However, warehouse management does not stop there. It needs ongoing maintenance and improvements to ensure the facility can operate optimally.

A goods-selling business’s success positively correlates with effective and efficient warehouse management.

To help our reader’s businesses succeed, this article will discuss:

- The key processes of warehouse management

- The principles of an effective WMS

- Its advantages and possible challenges

- The best warehouse management software for small businesses

Thus, without further ado, let’s get straight to the discussion!

What Is Warehouse Management?

Broadly defined, warehouse management refers to controlling and optimizing warehouse operations. It includes all inventory-related movements, employee training and supervision, shipment controls, etc., in the facility.

A business must have an up-to-date warehouse management system (WMS) if it wants a productive workflow. Let’s look closer at how such systems operate in practice.

What Is a Warehouse Management System (WMS)?

A warehouse management system (WMS) is software for businesses to optimize warehouse processes. It provides real-time visibility over inventory levels and movements, sales statistics, demand forecasts, and many more.

Such systems integrate with a business’s existing software, including enterprise resource planning (ERP) and order management systems (OMS). Effective organization and execution of warehouse processes are crucial to a business’s success as they can lead to increased productivity, happy customers, and ultimately, higher profits.

With the help of a warehouse management system, the manual work and human errors decrease, the accuracy of snapshots increases, and companies save a lot of time. There is also less need for continuous warehouse audits and cycle counts due to the rise in the effectiveness of timely management procedures. Inventory audit is integral to warehouse management and is only possible with an advanced WMS.

Standard Functionalities

The features of warehouse management systems vary according to the specific needs of businesses. However, certain standard functionalities are present in most, if not all, systems. These include:

Inbound Management

The function streamlines the receiving process of goods and notifies the staff about the arrival of new inventory. It keeps track of what needs to be received, from whom, and in what quantity.

Inbound management is beneficial as it increases the accuracy of inventory data and helps businesses avoid stock-outs. Moreover, it enables businesses to track the progress of inbound shipments and optimize the receiving process.

Put-away Management

This function streamlines the process of storing inventory in the correct storage location. It helps businesses save time and avoid errors in inventory placement.

Put-away management is essential as it prevents inventory from being misplaced. Due to this, businesses keep track of their inventory levels across all storage locations. In case of a stock-out, managers can quickly identify the root cause and address it accordingly.

Picking Management

The function helps businesses select the correct inventory for customer orders. It ensures the picking and dispatching of the right products on time. While picking management is crucial to reducing errors in customer orders, it also helps businesses step higher than their competitors.

Most warehouse management systems offer load management, slotting, cross-docking, catalog management, and other functionalities.

Critical Processes in Warehouse Management

Warehouse management is integral to supply chain activities, affecting inventory management, order fulfillment and shipping processes, etc. It includes several sub-processes. Find the key ones below.

Inventory Tracking

Inventory tracking refers to the control of stock levels, which allows you to know the exact locations of your goods, such as their place in storage, transit points, etc. It is also essential to determine whether your stock volumes are enough to meet customer orders or create optimal ordering schedules. With the business growth and expansion, the inventory turnover and volumes increase, and the tracking becomes more challenging. Despite the complications, businesses should still aim to maintain accuracy. Thus, solutions like eSwap help people involved in the retail industry to visualize and manage their inventory more efficiently. It provides users with complete inventory reports to ensure the safety of their goods and avoid potential issues.

Receiving and Storing

One of the significant processes conducted in the warehouse is the receipt and storage of new inventory. After scanning each inventory item received, the system transfers them to the planned location in the storage. Reasonable and adequate storing is vital to ensure that the warehouse space is optimally organized and no extra costs occur because of poor storage area management.

Picking and Packing

After receiving an order from a customer, the picking and packing processes occur in the warehouse. Using a picking list, which indicates the order data, warehouse employees pick the correct goods and hand them off to the packers. Packing refers to safely and securely placing ordered goods into a box or other packing materials and adequately labeling it for shipment. If there is a delay occurring in the picking-packing processes, it will result in a decrease in customer satisfaction.

Shipping and Delivery

The final step of an inventory unit in the warehouse activities is shipping. Usually, the shipping service-provides perform deliveries to customers, such as DHL, FedEx, UPS, etc. Although they pick up the packages and ship them to the ordered location, the warehousing team still tracks the process to avoid any issues and keep the customer updated on the status of their order.

Warehouse Management Principles

The most important thing to discuss is how to ensure the effectiveness of warehouse management processes. To do that, consider keeping in mind the following principles when developing warehouse management approaches.

Aim for Data-Driven Decisions

Instead of building abstract assumptions based on nothing more than just intuitions and opinions, constantly review data, statistics, and analytical reports. Ensure that behind every decision, there is conscious, data-driven analysis. Even if there are seemingly no problems occurring, there is still a possibility that the processes are not conducted in their maximum capacity of effectiveness. So, review and use data even when there are no emergency cases.

Warehouse management software that can provide precise analytics and reporting is a precious finding. It allows you to evaluate and compare different scenarios to make better-informed decisions.

Ensure Complete Supervision

Employees should be responsible for the overall control of the warehouse. That task is usually under the responsibility of a warehouse supervisor or the head of logistics. To increase the effectiveness of the control systems, they can initially create trackable workflows for warehouse teams. The key to supervision is to ensure that each team member is aware of their tasks and operates to the maximum level of productivity. However, if you want your business to succeed, be ready to review and update all internal processes from time to time.

Be Flexible and Adapt to Changes

It is impossible to ensure 100% certainty and stability in business operations, including warehouse management. Considering external and internal factors, businesses should smoothly change their procedures, practices, and plans accordingly to avoid losses.

For example, during the COVID-19 pandemic, online sales increased dramatically. According to the United Nations Conference on Trade and Development reports, online retail sales in the US alone amounted to $598 billion in 2019 and $791.7billion in 2020. It is an increase of more than 32%. So, many businesses had to update warehousing operations to meet the new demand trends.

While warehouse management software increases operations’ flexibility and scalability, the people matter just as much. Thus, it is crucial to have an advanced tech solution to assist the team of professionals who can quickly adapt to new conditions and find the best for the business.

Invest in Technology

Technology with a wide variety of tools helps improve warehouse management processes’ functionality. Modern technology is a must to succeed in business, especially in the case of inventory and warehouse management, where the team should efficiently complete various tasks to avoid any losses.

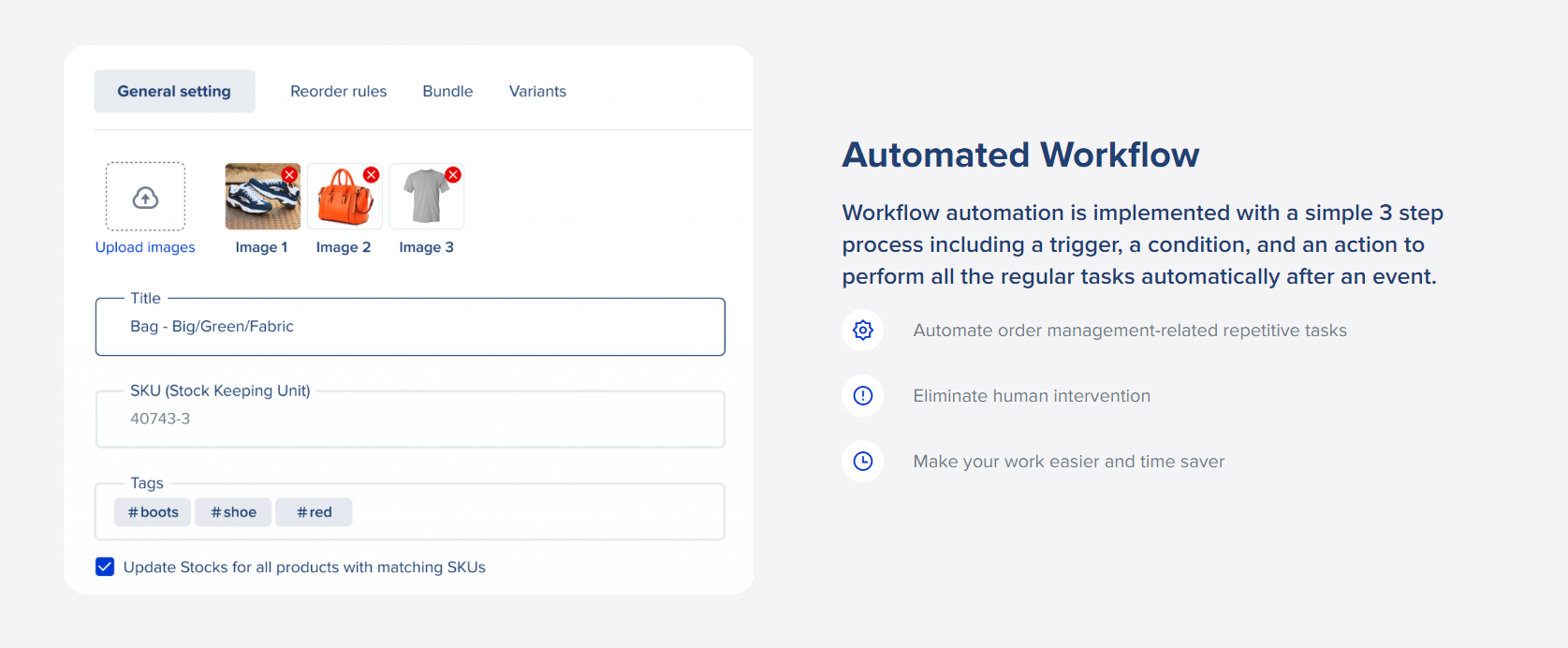

Businesses should use warehouse management software that would allow them to automate and digitalize most business-related operations to achieve the best results. Automation increases accuracy and efficiency while reducing human errors and miscalculations.

The Advantages of Investing in Warehouse Management Software (WMS)

WMS is crucial for businesses that aim to optimize and streamline their operations. The system’s advantages are significant and can provide a considerable return on investment. Here are the key benefits of using WMS:

- Efficient inventory management – WMS allows businesses to track and manage inventory levels in real-time. The system provides complete visibility of products in stock, location, and the precise restock dates.

- Improved order picking – WMS systems use algorithms to generate optimized pick paths that help warehouse employees save time while picking orders. The software tracks inventory levels and can create reports to help businesses avoid stock-outs.

- Lower operating costs – It can automate many tasks, such as order picking and inventory management. Automation can help businesses save money on labor costs while significantly increasing accuracy and efficiency.

- Increased customer satisfaction – With such systems businesses are certain order fulfillment is never late and that customers receive their orders in perfect conditions. If anything goes wrong, the system will quickly generate a report, and you can solve the issue before it becomes a bigger problem.

- Improved decision-making – WMS systems provide businesses with real-time data to make informed decisions about warehouse operations. The software can also generate reports that help companies to track and analyze trends.

A Few Challenges of Warehouse Management Software

Still, like any other business operation, warehouse management has a few challenges. The most significant ones are:

Law Traceability Levels

Businesses need to meet specific requirements regarding the products they store. These include expiry dates, batch numbers, and product origins. The WMS should have a feature that allows businesses to track and update this information.

Manual Data Entry

Businesses relying on spreadsheets or other manual methods to track inventory are at a higher risk of human error. Investing in WMS that can automate data entry and provide accurate real-time updates upon changes in inventory levels is crucial.

Lack of Scalability

Businesses need to be able to scale their warehouse operations according to their needs. If the WMS is not scalable, it will become a burden rather than a solution.

Luckily, eSwap has all the must-have tools to avoid the challenges mentioned above. This free warehouse management software is easy to use and can quickly integrate into the workflow without any significant changes to your current operations. eSwap is the best warehouse management software for small businesses that want to upscale and become better than their competitors. The software is a real helping hand that will control all tough tasks while you focus on what’s important – your business goals.

The Bottom Line

It’s essential to be aware of the key processes and principles involved in its operation to make the most of your warehouse management software (WMS). By understanding these, you can ensure that your WMS works as efficiently as possible for your business. Of course, with any new system, you will always face new challenges, but with careful planning and execution, these will become minor priorities.