Customers got used to expecting to get their orders fulfilled early. This has made the job of warehouses quite challenging and takes all the steps very seriously. Warehouses should regularly care about keeping inventory. So, inventory replenishment becomes the core factor. It ensures an efficient flow of goods during their way through the supply chain stages.

That’s why we focus on this notion today. Let’s view automated replenishment systems and inventory forecasting. As well as their planning as a supply chain strategy.

What is Inventory Replenishment?

Inventory (stock) replenishment is a supply chain process. It shows the inventory going from different types of storage locations. The types are reserve, primary, picking locations. The term can be used to describe raw materials as well. Here also inventory that is ready to be sold is included. And it’s the suppliers who send them usually.

Inventory replenishment is a mix of practices and technologies. They help with inventory management. Mainly those that go from various supply chain components. Stock replenishment aims at utilizing the most successful methods of moving inventory.

What are the goals of Inventory Replenishment?

Stock replenishment covers all connected to the warehouses. If organized right, it will solve the main warehouse processes, like:

- Prevent overstocks

- Support on-time deliveries

- Reduce labour costs

- Reduce deadstock

- Minimize the risk of logistical problems

- Prevent shortages

- Improve replenishment planning

- Meet customers’ demands

- Ensure enough safety stock amount

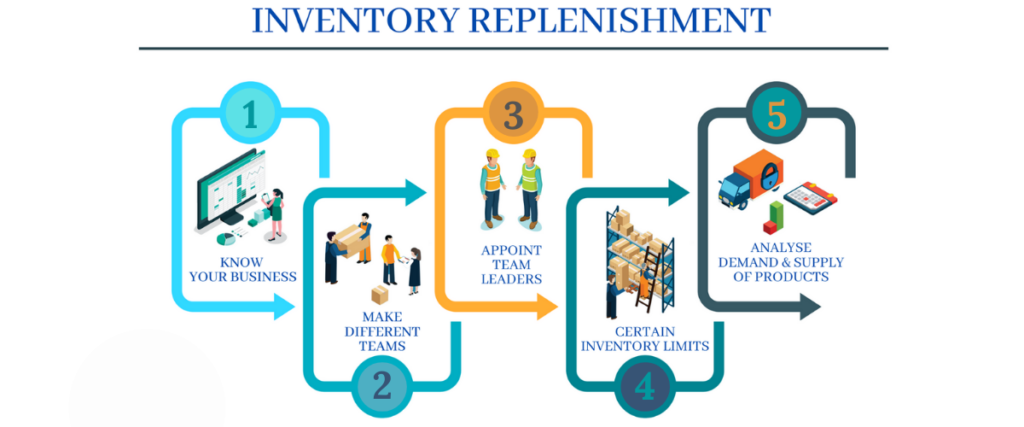

How does replenishment work?

A good warehouse works as a part of a well-organized and proper business. It should have its own rules to replenish. Those should be based on the global supply chain management rules. Usually, they are fixed in a written form. Also, they depend on the forecasted demand. But they can be adapted to situations and issues.

To make replenishment, first of all, there should be a business team. As a rule, they consist of managers and planners. Together they focus on ensuring a sufficient amount of stock items. It helps to manage high-quality order fulfillment. And the central point to deal with is order counts. For example, when the counts fall to the reorder point. The responsible worker contacts the other side for item replenishment (both for ready-to-sell inventory and raw materials).

What affects inventory replenishment?

Issues and work process pitfalls can happen everywhere. Even in the systems working strictly according to their plan. People in the company will tell the best about the causes and reasons. People can tell about problems in the warehousing workflow. For example, warehouse or product managers, vendors and typical workers. And If you ask any of them, you’ll probably get the same answer.

The main cause of stressful situations is failing replenishment planning. That’s because the key to the success lies in its replenishment strategy. But of course, there also can happen some random situations. The main components that affect can be changed. It happens because of the company forecasts, badly optimized workspace, low-quality visibility.

Models for Inventory Replenishment

We have already discussed the most important. Companies should organize replenishment before the hence process. So various models should be thought out for better workflow. There are some commonly used and well-known models. They help determine the number of items. Plus other essential components of warehouse management. They are listed below.

Demand Inventory Replenishment

This model is suitable for some warehouses. For instance, those where there are little space and limited picking location. Here replenishment takes place just for pending orders fulfillment.

Minimum and maximum inventory replenishment

Another name of this method is the Routine method. Its main idea is setting min and max thresholds. After the items reach those numbers, workers reorder the stocks. For instance, this is a suitable method when predicting seasonal demand. The inventory levels here constantly review. And after reaching minimum and maximum, replenishment orders occur.

Top-off Inventory Replenishment

This method is similar to the min and max. They fulfill it according to the schedules. This method works well when you expect amount changes.

Periodic Inventory Replenishment

For this method, specific time intervals are used. Inventory for certain intervals goes to locations to pick. And inventory gets reviewed at the end of those intervals. At this step, workers count inventory and find out the in-stock amount. As soon as stock levels are lower than the minimum, replenishment gets ordered. If not, the process is skipped till the next interval.

Stock Replenishment Systems

Imagine a business with a good name and sales history. It has also got a massive amount of work to do. There are so many goods to manage and track. There are also some issues. For instance, customer preference changes. Also, seasonal changes connected to the demand, old products, etc. And it is challenging for people to do it manually. Business holders need precise demand prediction and planning. For this developers have thought of some automated supply replenishment systems. Such as inventory replenishment systems. We present the leading 4 of them.

ERP – Enterprise Resource Planning

Inventory management features include ERP solution. It makes it easier to organize, track the items. Chiefly in the whole supply chain way. It also makes their packing and picking faster.

Warehouse Management Systems

WMSs give so many advantages to the users. Managers can set a certain amount for each product item. The amount of items falls lower than the minimum. Then the system automatically creates protocols. And then the program sends orders to replenish.

eSwap is one most eminent examples of WMS. The platform supports accurate real-time data. Also demand overseeing, and so much more for warehouse high-quality work. Therefore, all these lead to replenishment activities boost and improvement.

Warehouse Execution Systems

WESs are also one of the most popular solutions for inventory replenishment. They help to raise demand, maintain dynamic orders and support better replenishment control.