Warehouses are one of the main parts of supply chain management and have a great impact on the technical and operational structure of the company. Warehouse management is considered successful if all the logistic processes are not time-consuming and costly, deliveries are made in time and customers are happy and satisfied. Consequently, modern businesses should design and optimize warehouses to get high efficiency. Most of them make these optimizations based on existing previous experience and successful methods. In today’s article, we are going to list warehouse organization tips from the technical structure of warehouses up to main warehouse operations.

Keep in mind these warehouse organization tips to manage and control warehouses in different locations of the world and get higher revenue.

Organize your Warehouse space

Optimizing your space includes the simple layout design. Be sure that the structure of warehouses matters a lot in productivity and impacts on any task implementation greatly. Optimization shout starts from the shape of blocks (length, width, quantity) up to the input and output doors of your warehouses. These improvements will help you save more time and free space and enable you to accomplish any daily tasks more easily and effectively.

Provide Warehouse maps

Maybe you offer one of the highest quality products in the world but fail because of not being accurate in mapping your warehouse locations causing late order fulfilment. Mapping enables you to code locations to simplify your employees’ communication and decision making, at the same time fasten shipping and delivery processes.

Classify Inventory

It is really difficult to find a certain product among tons of variants and types. The only thing that can help you to overcome this situation is classifying your inventory. Use special SKUs to sort your inventory by size, quantity, color, shape. Additionally, be sure to manage your products based on movement correspondingly fast, medium, and slow movers.

Slot your inventory

Because picking orders are a timely process it is a must to slot your inventory. Warehouse slotting refers to the process of distributing your inventory in warehouses. Effective warehouse slotting reduces handling costs and labour efforts by maximizing space and simplifying the order picking.

Manage inventory receiving

When it comes to warehouse management, one of the main tasks is managing inventory retirement. It should be the starting point for further operations. These activities include receiving orders from suppliers and shelving.

Automate your storage

Most businesses prefer storage automation aimed at saving much time. Business owners confirm that automation increases inventory management efficiency in a very short time.

Manage safety stock

Safety stock or also called buffer stock is the guarantee of having no risk of supply chain failure. Particularly small and mid-sized businesses should carry safety stock to ensure to overcome any problem caused by unexpected changes in demand.

Keep warehouses clean

Keep clean warehouses-these are not only words but it should be done practically. Be sure it plays a vital role in your success. First of all, it is directly a message to your business team to show how you care for their safety and health. The clean and organized warehouse will simplify and make your business process management easier.

Maintenance of your equipment

What do you think is the reason why the maintenance of equipment is important in production processes? You are all right, it will help you avoid any breakdowns, production losses, cutting replacement costs, and generate high revenues.

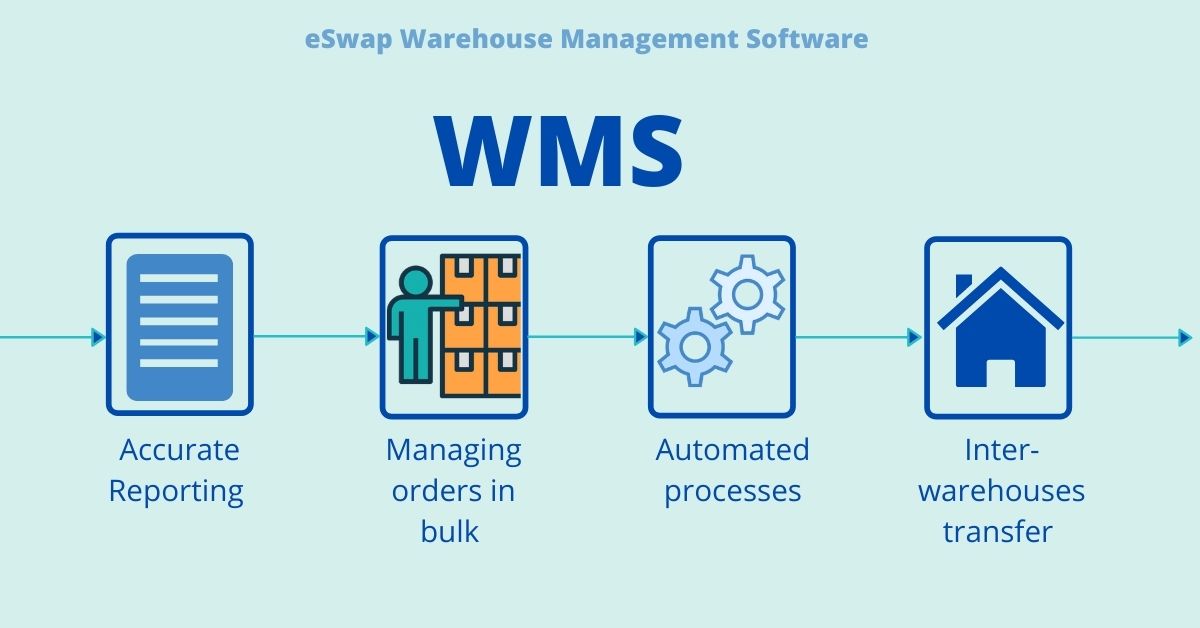

Integrate WMS

A warehouse management system (WMS) is an automated software managing and optimizing warehouse operations and any business inventory process. It is aimed at minimizing manual tasks, spreadsheets usage, and available human errors, which in turn will increase efficiency and accuracy.

eSwap Warehouse Management Software

Considering the importance of such kind software eSwap has launched its warehouse management feature to enable you to coordinate your warehouse and distribution center processes and sell products without losing any data.

eSwap users have already tried it and got benefits.

eSwap provides accurate analytics to allocate your products through special warehouses and get high visibility of them.

eSwap offers automated announcements and alerts to enable you to get overstocking or low-stocking notifications and solve them ASAP.

Additionally, eSwap allows transferring any data and inventory from one warehouse to another in real-time.

Finally, eSwap has integrations with world-known powerful sales channels and marketplaces.

Stop spending money and efforts on time-consuming processes and join eSwap with a 14-day free trial opportunity.