The Order Fulfillment Process includes operations of receiving goods and sending them to the end consumers and starts with product purchasing and includes the order returning operations as well. The order fulfilment process consists of several stages. Nowadays, customer satisfaction matters more than ever.

With the help of this article, we will discuss all of the steps involved in the order fulfillment process and its main models.

What is Order Fulfillment?

Order fulfilment is the process of receiving goods, processing them and finally delivering them to consumers. The moment the customers buy products, the order fulfilment process begins. When the customer successfully receives his products, it means that the process is ended. There are, of course, cases when your customers will return their orders, and the order fulfilment process includes this stage as well.

Take a look at the main detailed steps involved in the order fulfillment process:

- Receiving inventory shipments

- Inventory storage

- Order processing

- Picking

- Packing

- Shipping

- Returns processing

eCommerce order fulfilment sometimes might turn into a difficult and complex process. It highly depends on the methodology the companies opt to handle their order fulfilment processes. There might be companies who choose to have an in-house fulfillment, while others might choose third-party logistics companies or 3PLs. Here is why you should choose the right order fulfilment center as well as the right model for your business.

Let’s now discuss the main stages of the order fulfilment process and later turn to the models as well:

Receiving Inventory

There are many sources where the inventory might come from. Here you have two options- either choosing to receive and handle your inventory in-house by yourself or ask the externals or outsourcers to do it. In case you decide to take care of your stock by yourself, note that you should be ready to count and inspect the whole stock. Apart from it, you should check up for the acceptable quality.

Inventory Storage

The moment you receive your inventory in your order fulfilment center, you should start sorting it. Inventory sorting should be organized. In that way, none of your product pickers will lose much time trying to find their desired product. There are different warehouse management systems, which will help you to acquire higher efficiency in this case.

Companies should remember the warehouse organizational tips as well, which will help them with the clever management and sorting of their stock. For example, if there are multiple product variances, the employees should separate them by SKUs in order to reduce the picking inaccuracies.

Order Processing

The order processing management system decides a lot in this case, including the pick and pack fulfillment. If you are responsible for order processing, you have to handle the overall fulfilment process. In the case of using order management solutions, everything becomes way much more effortless. You can easily integrate it with your different sales channels like eBay, Amazon, Walmart and many others.

eSwap’s order management allows to reduce the fulfilment costs and provides the sellers with real-time order syncing. In addition, everything related to order processing becomes manageable from one dashboard.

Picking

As soon as customers purchase a product, the information is sent to the warehouse staff or your fulfilment center. With the help of the WMS systems, you can identify the product locations easily as well as the units available per each SKU.

Thereafter, the pick and pack fulfillment begins. Your picker or the picking team selects the necessary product as requested in the packing slip. It includes information about the quantities, product colours, sizes, number of units and location in the distribution centre’s warehouse.

Packing

Then comes the time for product packing. The packing team or the automated fulfillment robots take care of it. They aim to provide the lowest or the most practical dimensional weights for shipping. The product dimension and weight are essential metrics.

Try to optimize the product dimensional weight (DIM weight) as much as it’s possible to provide quick transportation for your orders. Moreover, the more practical are the sizes, the more chances you’ll have to reduce the shipping costs.

It’s the packing team’s responsibility to take care of the return shipping material and labelling issues. This refers to the cases when customers decide to return or replace their orders.

Shipping

Once the package is ready with a shipping label, it can get ready for transportation. It is not big news that the shipping process is quite costly, and the shipping options depend on the company’s budget mostly. If you want to have fast delivery, you should be ready to pay for it. USPS shipping company is the ultimate choice for small business for their product deliveries. As soon as the packages are sent, the customers receive tracking numbers and other information to check their product delivery status.

Returns Processing

This is an unwanted process for most businesses. But if you take care of your customer satisfaction, you should be ready for this as well. In that way, you will not lose your customer flow and even support repeat purchases.

Return processing starts with collecting the shipping materials and attaching the return label to the customer’s order. If your consumers wish to exchange or refund the product, you should ensure that the process is as accurate as possible to restock it if you want to sell it again. The product return process assumes accurate checks for quality control.

Order Fulfillment Process Types

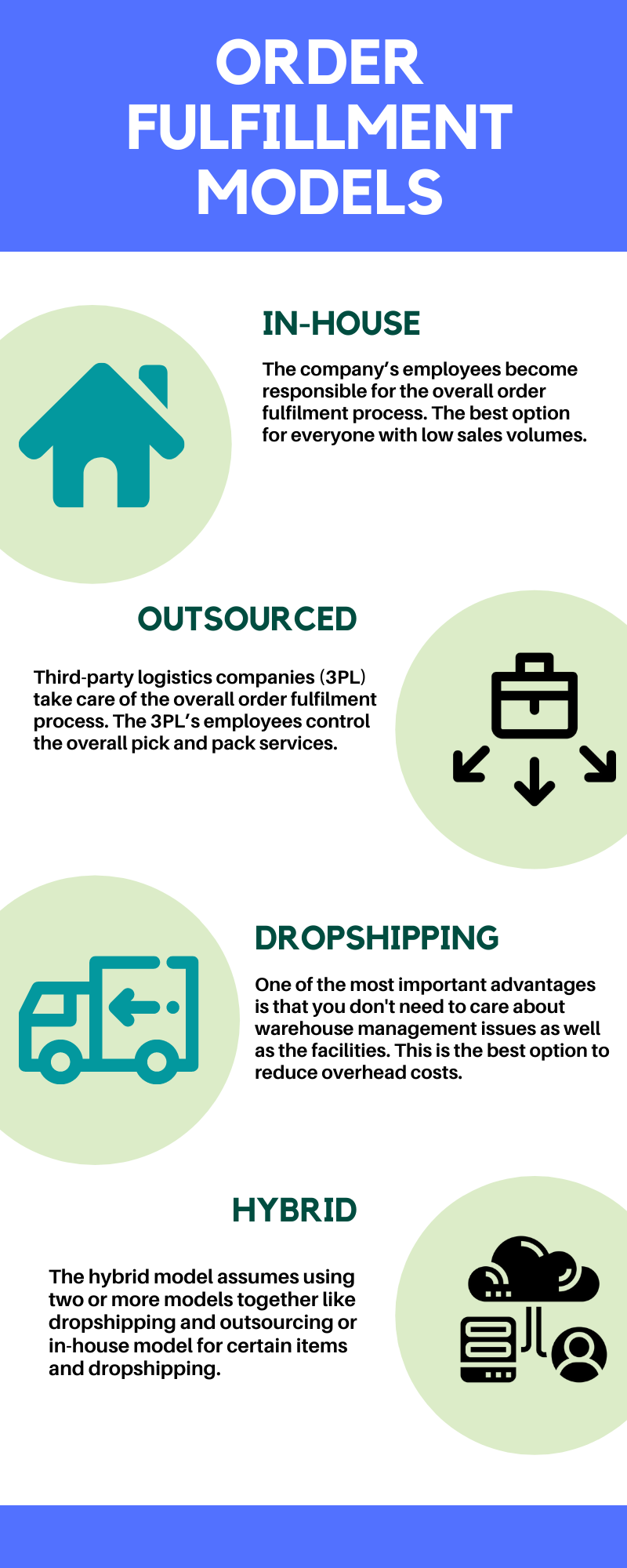

There are four order fulfilment models in retail. Each of them serves a specific business type and needs. Your choice should depend on the size of your business, your requirements and other aspects.

Let’s now study each model one by one:

In-House Model for Order Fulfillment Process

In this case, the businesses rely on their resources to take care of their fulfilment processes. The company’s employees become responsible for the overall order fulfilment process. It starts with inventory storage to end delivery. This model will work for small businesses with low-volumes of sales. The moment they begin to grow, most of them move to the outsourced or hybrid models.

Outsourced Model for Order Fulfillment Process

This is the best model when the overall order fulfillment process regarding the shipping storing, order/refund processing is taken care of by a third-party logistics (3PL) or order fulfillment company. In this case, the 3PL’s employees control the overall pick and pack services.

Also, the companies don’t need to think about the problems referring to their warehouse facilities.

Dropshipping Model for Order Fulfillment Process

This model is similar to the outsourcing model. Starting a dropshipping business is especially beneficial for e-commerce and startup businesses. In this case of dropshipping business, the retailers buy products from third-party suppliers. As the orders are produced and shipped by the manufacturers, the overhead costs are minimized. That’s the reason why many startups choose this model.

Hybrid Model for Order Fulfillment Process

The hybrid model assumes using two or more models mentioned above for your order fulfillment process. For example, you may choose to manage some stock that is popular among the customers and is of high demand in-house. In case of expensive or infrequently purchased products businesses may choose dropshipping. This model gives flexibility.